Optimal project preparation with a Kanban board.

Optimal project preparation

The start of a new project starts with the clearance of the existing interior.

Part of our project preparation is good logistics planning. We often hear that ‘projects should start as soon as possible’.

Part of our project preparation is good logistics planning. We often hear that ‘projects should start as soon as possible’.

The start date is not so relevant: a good preparation time is more important. With good research, we can use this to ensure that we know exactly what and how to build. Only then will the first activities be planned. Clearing, securing, disconnecting installations and dismantling can then be done in a few days. We start a little later, but the total lead time is shorter and the costs are lower. That’s smart building.

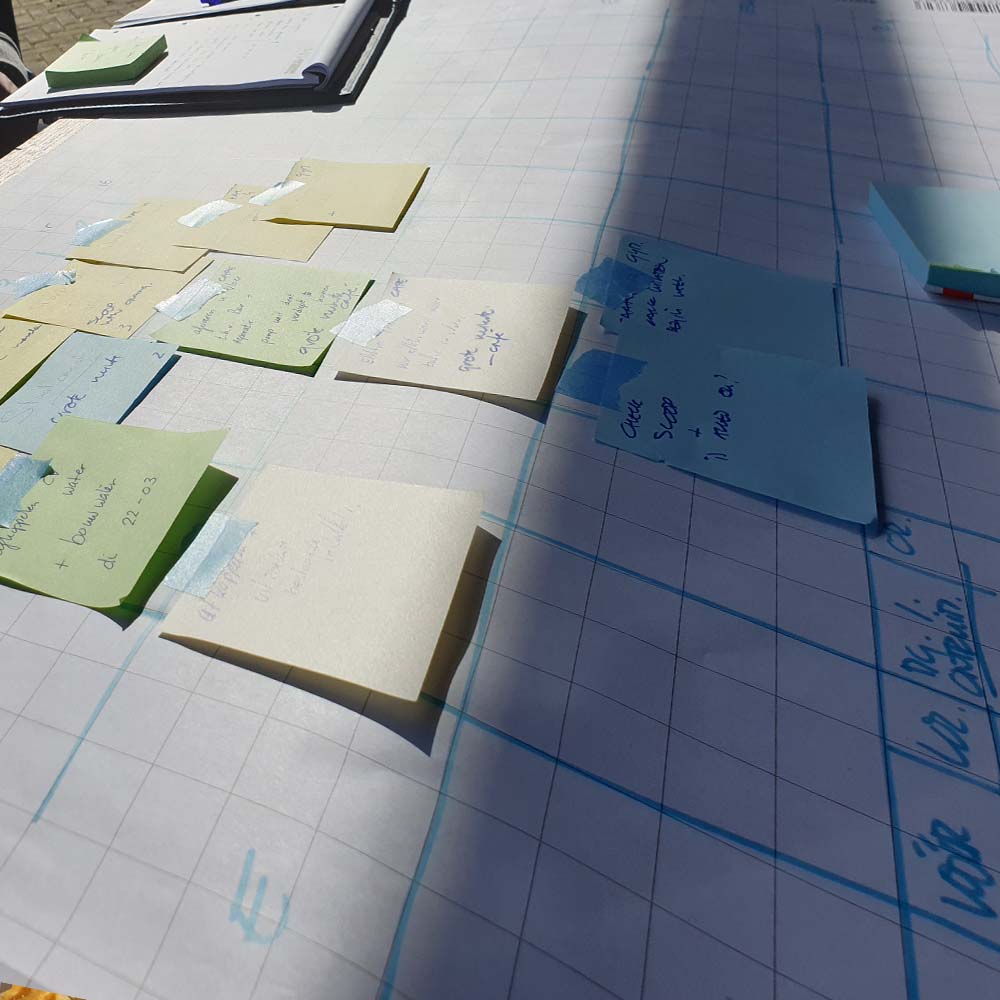

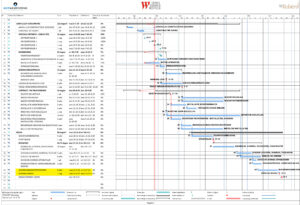

Kanban board

The project approach and planning is a team effort. And while many people often refer to sticking post-its as lean planning , it’s actually the Kanban board.

On the Kanban board, your team’s value stream shows you all the steps you take to create that value. And the most important thing here is identifying that value of your neighbor: what does one need from the other to be able to do his process step well. If that is put together in a schedule: then the Gantt chart follows with the lead times.

So what is lean?

Once you have mapped out those process steps and the ‘waste’, the process becomes ‘ lean ‘: adding as much value as possible with as little ‘waste’ as possible.

Lean is a way of thinking about how to add as much value as possible with as little ‘waste’ as possible. That actually relates much less to one project, but much more to continuous development. Constantly evaluating the team effort to get the superfluous space out of the production and processes: the ‘ waste ‘.

A number of considerations and questions always play a role during the KanBan session:

- What is the value to be added, or what is the problem to be solved? That does not always have to be the built end result: sometimes that unburdening the client or, above all, ensuring that the operation can resume as quickly as possible.

- What activities must be performed to achieve the goal?

- what capabilities and skills are needed to achieve that goal?

- what kind of leadership and management is needed: both in skills and management system?

- which way of thinking, including mindset and analytical skills, is needed to go through these steps properly?

For building together, that means taking the lessons learned from the previous project into each project and processing those experiences in the total. The Lean principle has been developed in the Toyota factories. It is a way of working aimed at improving quality with as little waste as possible. In the Toyota factories, every machine operator was allowed to interrupt production to work together on an improvement. Because production then came to a standstill, it became an effort from all disciplines for the entire chain to realize the improvement as quickly as possible and resume production.

If the result becomes Lean, efficiency is created, both in time and in the use of materials. Add to this a principle of JiT: Just in Time delivery and we arrive at a construction process and construction site as we envision it.

^Justus Slaakweg