Setting out digital dimensions for fast construction

Digital layout of dimensions

The renovation of the office of Mr. Green in Apeldoorn is in full swing. Part of NewArmstrong’s work is digitally measuring and then digitally plotting the dimensions. We set out digital dimensions so that the various disciplines of construction are well coordinated. The digital measurement can be done with a Faro Laser scanner or with the Sokkia Totalstation . Staking consists of entering fixed points in our drawing software and the points to be measured from the drawing. These dimension points are then read into the Totalstation. We use this to set out the dimensions of walls, installations and lighting, for example, on location.

Advantages of digital staking:

- the dimensions of all disciplines are mutually coordinated: this prevents failure costs

- the expanded dimensions ensure that, for example, installers can already start while walls have not yet been installed, but they can see exactly where they will be

- digital stakeout is faster than laser stakeout

- the contractor of the walls can start building walls at different places at the same time, while the mutual distance is exactly right

- the contractor of walls and installers can start building immediately after unloading the material, without first setting out the dimensions: this speeds up the construction and increases the daily production

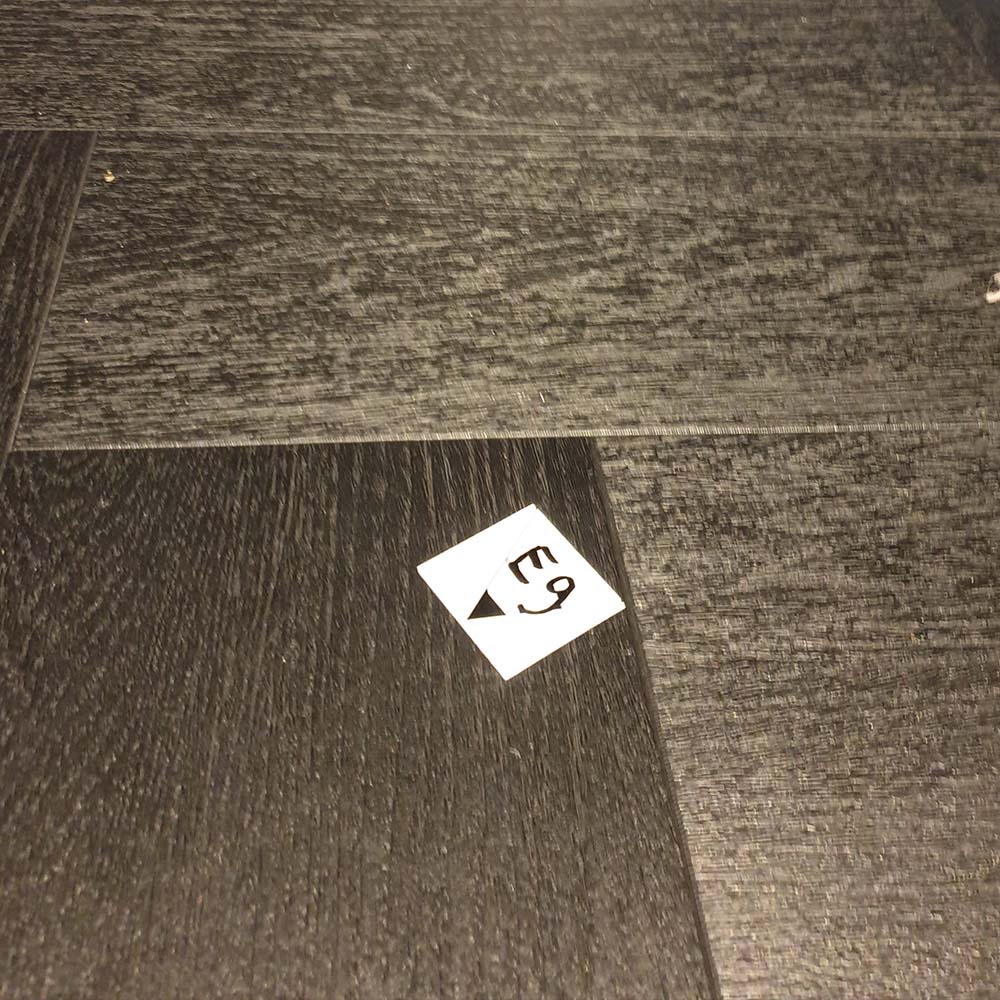

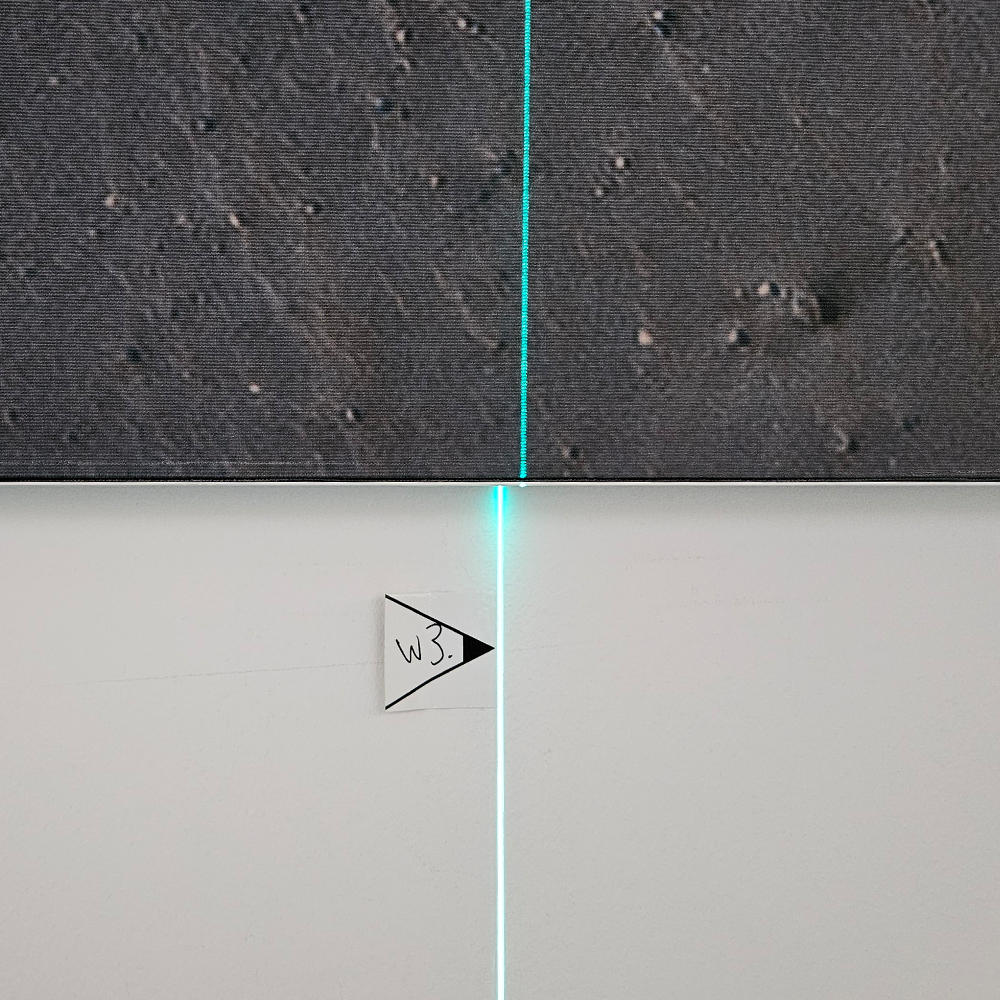

For stakeout we use a Sokkia Totalstation: this is a device that combines angle and position measurement with a laser distance meter in one device, so that every point can be projected in all three dimensions. The Totalstation projects a laser at the point where the dimensions must be plotted. Here we stick a sticker with the dimensions.

On that sticker is the number of the point that corresponds to the dimension drawing. The numbering corresponds to the coding of points: separate coding for walls, installations, lighting and furniture. The drawing is an important part of the communication: it clearly indicates, for example, what exactly has been measured. For duct and pipe work, for example, it is always the heart of the duct or pipeline. For sand-lime brick walls it is the edge of the wall, for metal stud walls the edge of the metal stud.

Whether we do our work in a place where there are still users or where construction is already underway: we usually switch it off after the working day or before the start of the working day. This ensures that users are not bothered by it, we do not get in the way of the contractor and that the work can start immediately the next day. After we have plotted the dimensions and marked all points on the floor, we place or paste the layout drawing on location so that every subcontractor who comes to work can work with the plotted dimensions. And we have very special stickers, which do not come off quickly, but which also do not leave any glue residue.

Would you also like to know more about speeding up implementation by measuring and plotting digitally? Please contact our surveying specialist Erik de Jong and staking specialist Lennart Mol. For contact details click here .

^Justus Slaakweg